For over a century, a global food manufacturer renowned for its household brands had earned consumer trust worldwide. Yet, rapid expansion and acquisitions had strained its outdated supply chain systems. Legacy technologies and spreadsheet-based processes were no longer fit to manage operations at scale, particularly when overseeing more than 10,000 ingredients and packaging materials across a complex network of global facilities.

As product lines diversified and markets grew more dynamic, the company faced a crucial turning point. Could a traditional supply chain be transformed into a smart, scalable ecosystem? To answer this, the organization envisioned a bold modernization journey powered by advanced technologies, enterprise-wide data intelligence, and a deep cultural shift in how value is created.

Modernizing systems to manage scale and complexity

The food company’s supply chain was vast but fragmented. Each regional plant operated on siloed systems, limiting agility and making it difficult to act on real-time data. Inventory bottlenecks, inefficiencies in procurement, and delays in production planning all impacted profitability and customer satisfaction.

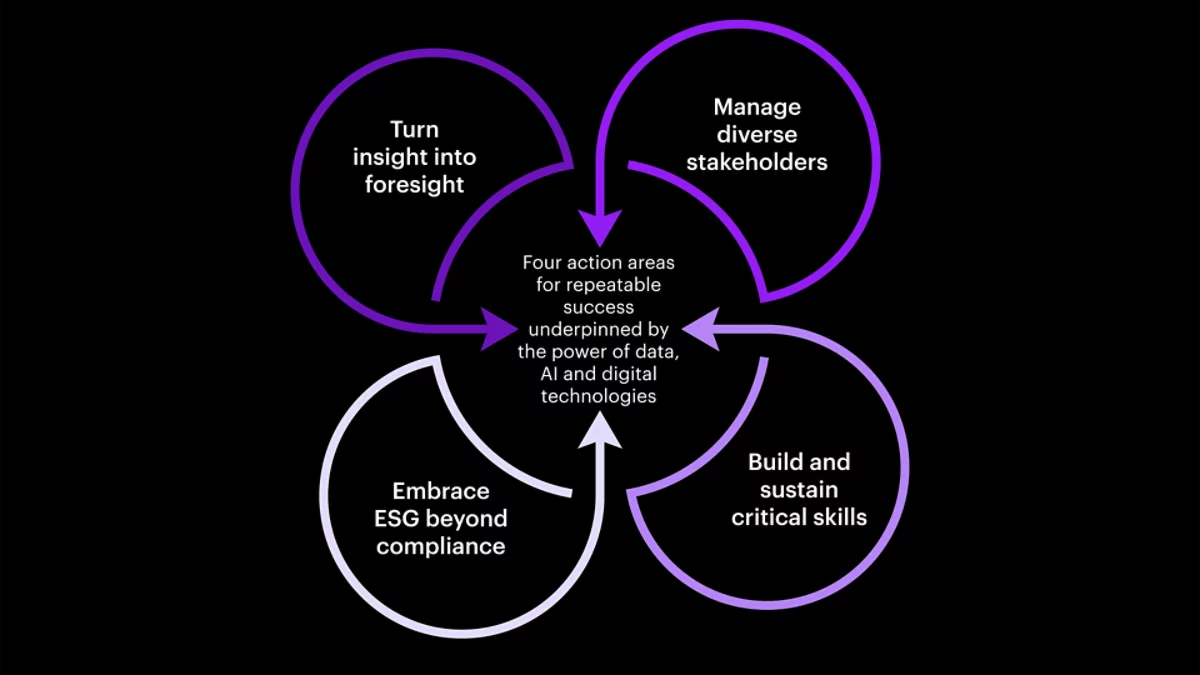

Trinet Technologies partnered with the company to tackle these challenges at the root—by building a digitally connected supply chain that could adapt, scale, and respond with intelligence. Our team leveraged AI, automation, and centralized data architecture to simplify global operations, improve supplier collaboration, and optimize production across geographies.

Data, AI, and people at the core of transformation

Beyond upgrading systems, the focus shifted to enabling people with the tools and insights they need. By replacing Excel sheets with dynamic dashboards and predictive analytics, teams now had access to accurate forecasts, real-time inventory insights, and actionable metrics. Automation of repetitive workflows freed up valuable hours, allowing employees to focus on strategy and innovation.

The result? Increased operational efficiency, better resource utilization, improved time-to-market, and higher employee morale—all while lowering operational costs and unlocking new revenue streams.

“Modern supply chains are no longer just about efficiency—they are engines of innovation."

From transformation to value creation

The journey is far from over, but the early outcomes speak volumes. The food giant now runs a smarter, more resilient supply chain that’s ready for the future. With digital maturity across production, sourcing, and fulfillment, the company is already seeing significant gains in operating income, and improved responsiveness to global market fluctuations.