Trinet Technologies has announced a strategic collaboration with OMRON Corporation to transform the manufacturing landscape by integrating Information Technology (IT) and Operational Technology (OT). This powerful alliance combines Trinet’s digital innovation capabilities with OMRON’s deep-rooted expertise in industrial automation to create a holistic, one-stop solution for intelligent manufacturing.

This partnership aims to balance economic performance with social responsibility by helping manufacturers achieve operational efficiency, enhance workforce productivity, and reduce their environmental impact through smart, connected technologies.

A One-Stop Ecosystem for Digital Manufacturing Transformation

Together, Trinet Technologies and OMRON will deliver a comprehensive service portfolio that merges factory-floor operations with enterprise-level intelligence. The collaboration brings together:

- OMRON’s robust OT suite—including advanced sensors, robotics, safety systems, servo drives, and control solutions

- Trinet’s cutting-edge IT solutions across cloud, AI, IoT, and digital twin technologies

This integrated framework will be offered as a unified solution, covering everything from strategic consulting and on-site implementation to system operations and ongoing maintenance. Target industries include automotive, semiconductors, electronics, life sciences, industrial manufacturing, and consumer goods.

Enabling Smart, Agile, and Sustainable Operations

Through continuous IT-OT synergy, this partnership will enable real-time data visibility, enhance decision-making, and drive sustainable growth. OMRON’s vast device ecosystem—over 200,000 SKUs—will feed rich operational data into Trinet’s digital intelligence platforms, such as our Asset Optimization Engine and Manufacturing Maturity Matrix.

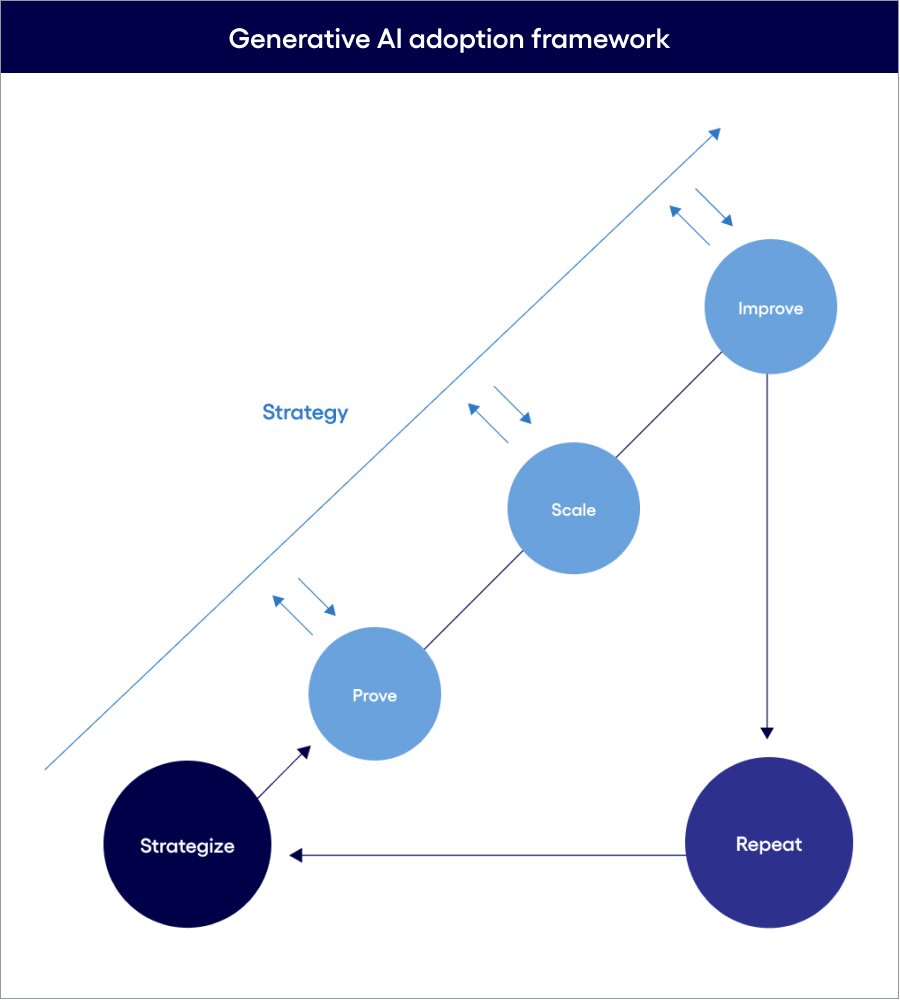

By integrating Trinet’s management-level analytics with OMRON’s real-time control data, organizations can pinpoint bottlenecks, prioritize improvements, and directly address shop-floor inefficiencies. These insights are seamlessly fed back into OMRON’s i-BELT data services and control applications, enabling a feedback loop that continuously improves operations and aligns them with strategic business goals.

"Our partnership with OMRON represents that shift. Together, we are building a unified IT-OT ecosystem that empowers manufacturers to operate smarter, faster, and greener. This is not just digital transformation—it is industrial reinvention.”

Pioneering the Next Era of Connected Manufacturing

This joint initiative is built to support a future where factories are not only smart but also autonomous, resilient, and eco-conscious. By leveraging emerging technologies and a collaborative business model, Trinet and OMRON are setting a new standard for manufacturing—one where human and machine intelligence work together to create lasting value.

From digital factory design to AI-powered quality control and predictive maintenance, this partnership addresses the most urgent challenges facing manufacturers today, including cost pressures, supply chain disruption, and the urgent need to reduce carbon footprints.