Nestlé, one of the world’s most trusted and long-standing food and beverage companies, has maintained a legacy of quality and global reach for over a century. With a vast portfolio of beloved brands and a presence in more than 180 countries, the company has long been a market leader. However, its rapid growth and series of acquisitions had outpaced its internal systems—particularly within the supply chain.

Behind the scenes, Nestlé’s supply chain operations were still heavily reliant on legacy platforms and siloed tools, such as spreadsheets, email chains, and disconnected regional systems. The result was a growing inability to manage real-time operations across continents, leading to delays, waste, and missed opportunities. The organization recognized the urgent need to shift from traditional models to a modern, resilient, and digitally integrated supply chain that could scale with the business and support its long-term sustainability goals.

Partnering for Innovation: Nestlé and Trinet Technologies

To embark on this critical journey, Nestlé turned to Trinet Technologies as a transformation partner. With deep expertise in supply chain digitization, cloud migration, data engineering, and intelligent automation, Trinet was uniquely positioned to reimagine and rebuild Nestlé’s global supply network.

The collaboration began with a comprehensive review of Nestlé’s supply chain—from procurement and production to warehousing, distribution, and logistics. Across thousands of SKUs, tens of thousands of supply items, and a footprint that spans dozens of production facilities worldwide, Trinet designed a customized transformation roadmap. The plan prioritized high-impact areas such as:

- Modernizing outdated production systems with cloud-based ERP solutions

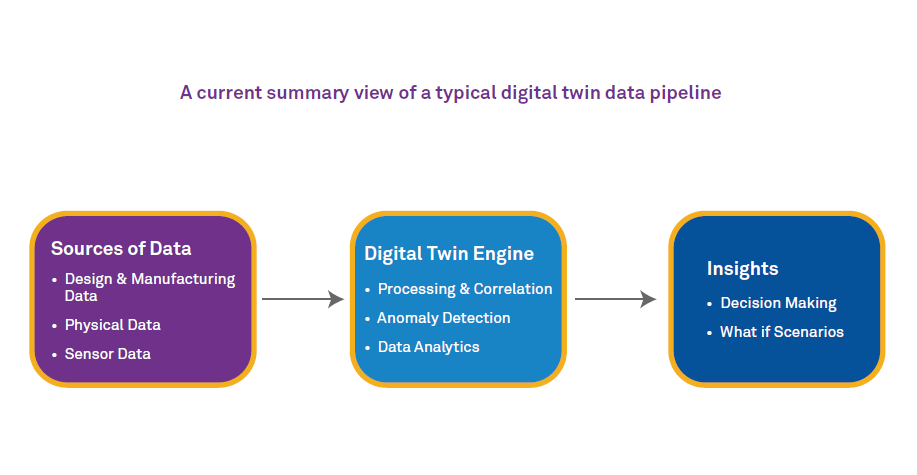

- Integrating fragmented data pipelines into a centralized, real-time intelligence layer

- Using AI and machine learning to predict demand, optimize inventory, and reduce spoilage

- Automating repetitive workflows to reduce manual errors and enhance employee efficiency

- Enabling end-to-end visibility with control towers and integrated dashboards

This shift was not just technological—it was strategic, organizational, and human-centric.

From Vision to Value: Implementing a Smarter Supply Chain

Over the course of 18 months, Trinet Technologies led a phased rollout of the transformation across Nestlé’s global supply chain infrastructure. The implementation included intelligent forecasting tools, automated procurement systems, real-time production tracking, and responsive demand planning models.

Production facilities that previously operated in isolation were now part of a unified digital ecosystem. Plant managers could view real-time metrics. Regional hubs gained control over inbound and outbound logistics. Executive teams had access to predictive analytics to support better capital planning and sustainability tracking.

Just as importantly, Trinet worked closely with Nestlé’s global workforce—more than 20,000 employees—to enable change management and upskilling. Training modules, hands-on workshops, and collaborative tools ensured that people—not just processes—were equipped for the future.

"Our collaboration with Nestlé proves that digital transformation—when done holistically—can turn a century-old operation into a smart, scalable, and sustainable powerhouse ready for the next century.”

The Outcome: Resilience, Speed, and Global Agility

The results of this transformation have been significant. Nestlé has reduced operating inefficiencies, improved order fulfillment accuracy, and achieved a faster time-to-market for its diverse product lines. Data-driven insights have improved decision-making at all levels—from sourcing ingredients to launching new product variants.

What was once a fragmented and reactive supply chain is now an integrated, proactive, and intelligent engine for growth. Nestlé is better positioned to handle market disruptions, regulatory changes, and evolving consumer expectations in real time.

The transformation has also supported Nestlé’s ESG goals—enabling better tracking of emissions across suppliers, reducing material waste through smarter demand forecasting, and optimizing shipping routes to reduce carbon output.